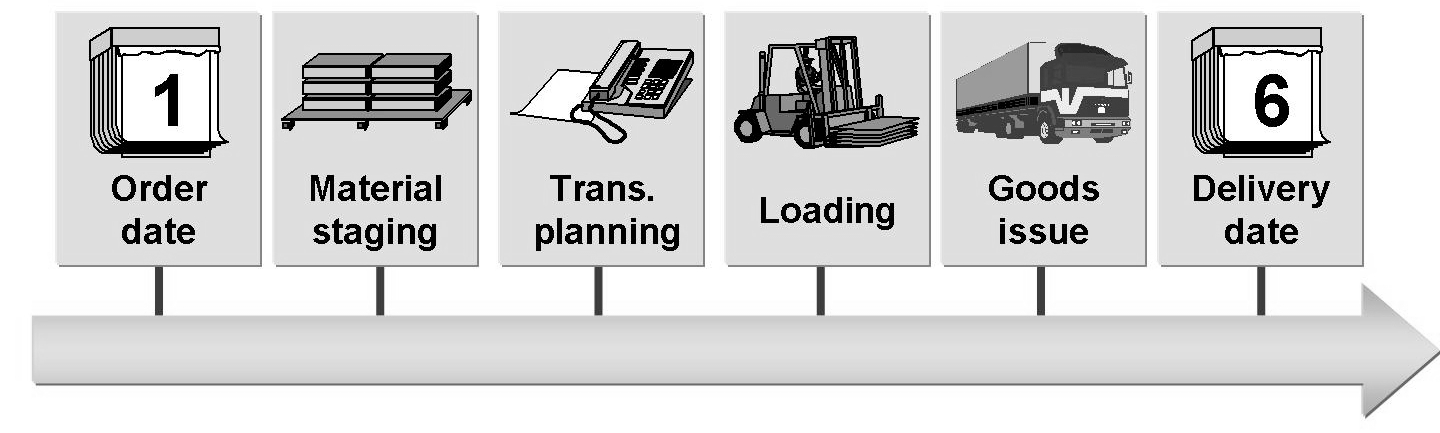

Shipment Scheduling in Delivery Process:

In shipment and transportation scheduling, you define the time at which the receipt of the goods at the customer can be acknowledged (confirmed delivery date). Different lead times are taken into account: the preparation time, loading time, transportation lead time, and transit time.The following data is used in shipment scheduling:

- Order date: date on which the order is placed • Material availability date: date by which a sufficient quantity of goods must be available for picking and packing

- Loading date: date on which the goods picking and packing process is completed (and the mode of transport is available) so that loading can begin on time

- Goods issue date: the date on which the goods must leave the delivering plant so that they reach the customer on the agreed date

- Delivery date: date on which the goods arrive at the customer. A differentiation is made between:

Shipment Scheduling Strategy:

When a delivery date is determined, you can also take into account the times required for delivering goods to a customer via a particular route.

The total time includes:

- Transit time: The time required for transporting the goods to the customer

- Transportation lead time: The time required for preparing the goods for transportation

The goal of shipment and transportation scheduling is to confirm a delivery date for a material requested by a customer.

Backward Scheduling:

For backwards scheduling, the customer’s requested delivery date is used to calculate the material availability date and the transportation lead time. The outbound delivery must be created at the earliest of the two dates (selection date for the outbound delivery).

- If both dates are after the order date and the material is available on the material availability date, the customer’s requested delivery date can be confirmed. A schedule line is created for the sales document item. The date of the schedule line displays the confirmed delivery date that is the same as the customer’s requested delivery date.

- If one of the two dates is before the order date, confirmation of the requested delivery date cannot take place. Therefore, the system attempts to determine the next possible date (forward scheduling).

Forward Scheduling:

If the result of backward scheduling means that the delivery date required by the customer cannot be confirmed, the system executes forward scheduling.

- Forward scheduling takes into consideration the time parallels of the work flows for transportation planning and picking/packing of materials. The longer of the two periods is relevant for scheduling. The selection date of the outbound delivery is the earlier of the material availability or the transportation planning date.

- The earliest date at which the material is available in the warehouse is the new material availability date. This is the outgoing point for new delivery scheduling.

Two schedule lines are generated for the sales document item:

- The date of the first schedule line corresponds to the customer’s requested delivery date and has no confirmed quantity.

- The date of the second schedule line shows the confirmed delivery date and the confirmed quantity.

No comments:

Post a Comment